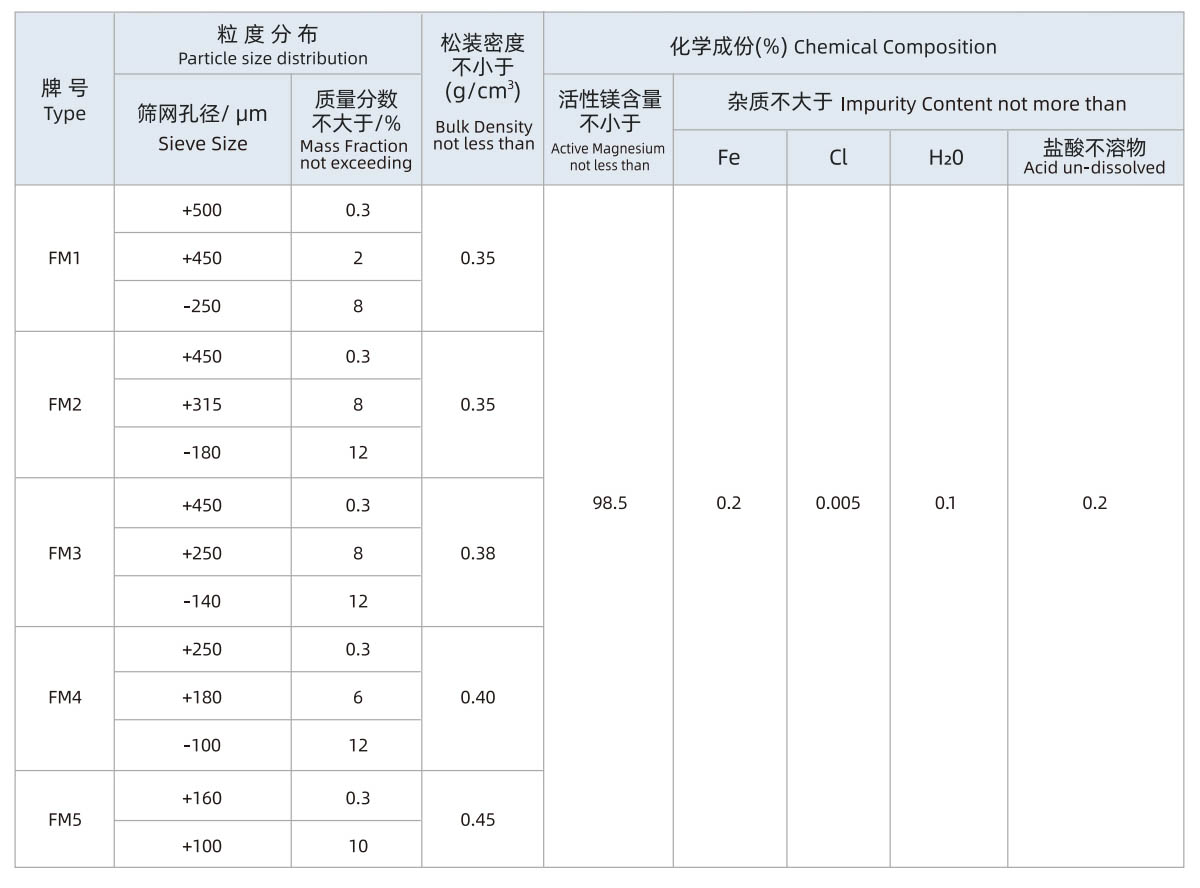

Magnesium Powder(Milled Magnesium Powder)(GB5149.1-2004)

Application

It is used in Military,fireworks,and chemical industry.

Specification

Can be produced according to user demand.

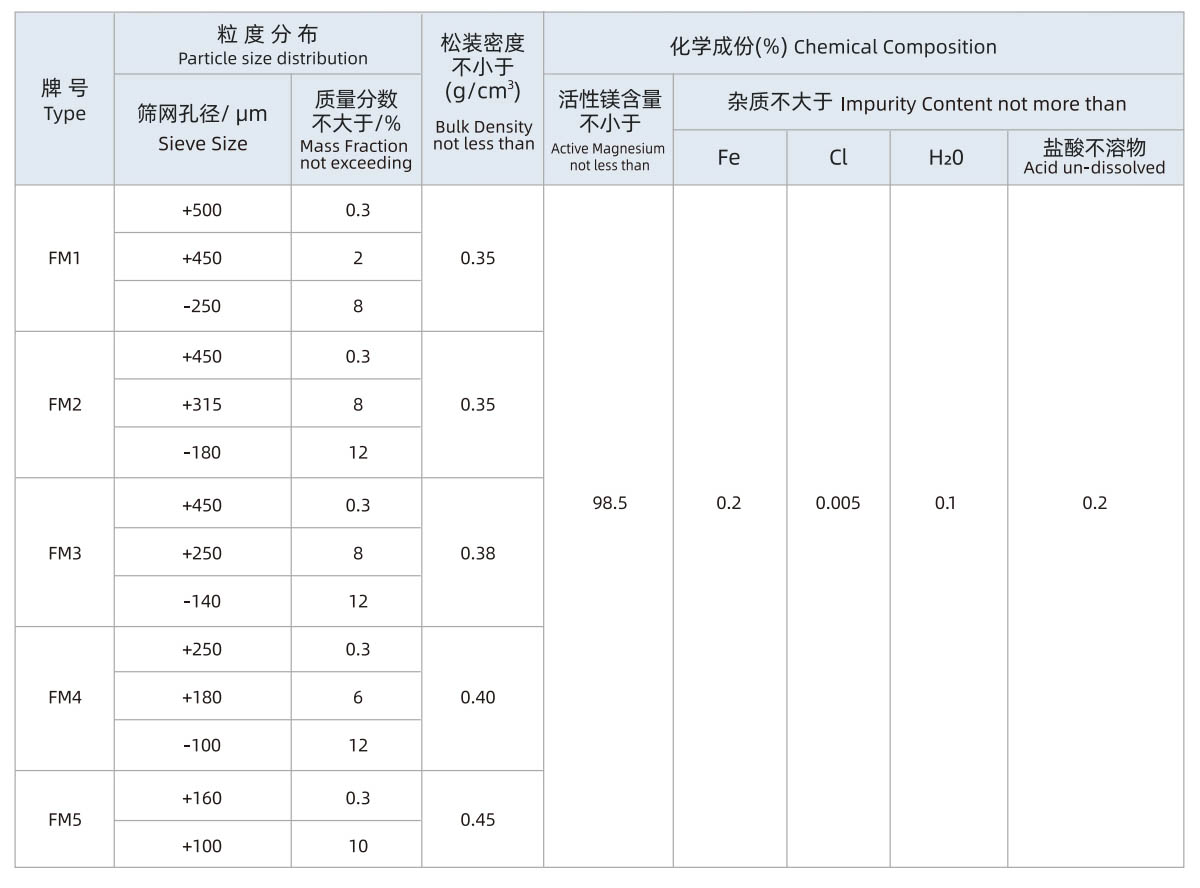

Application

It is used in Military,fireworks,and chemical industry.

Specification

Can be produced according to user demand.